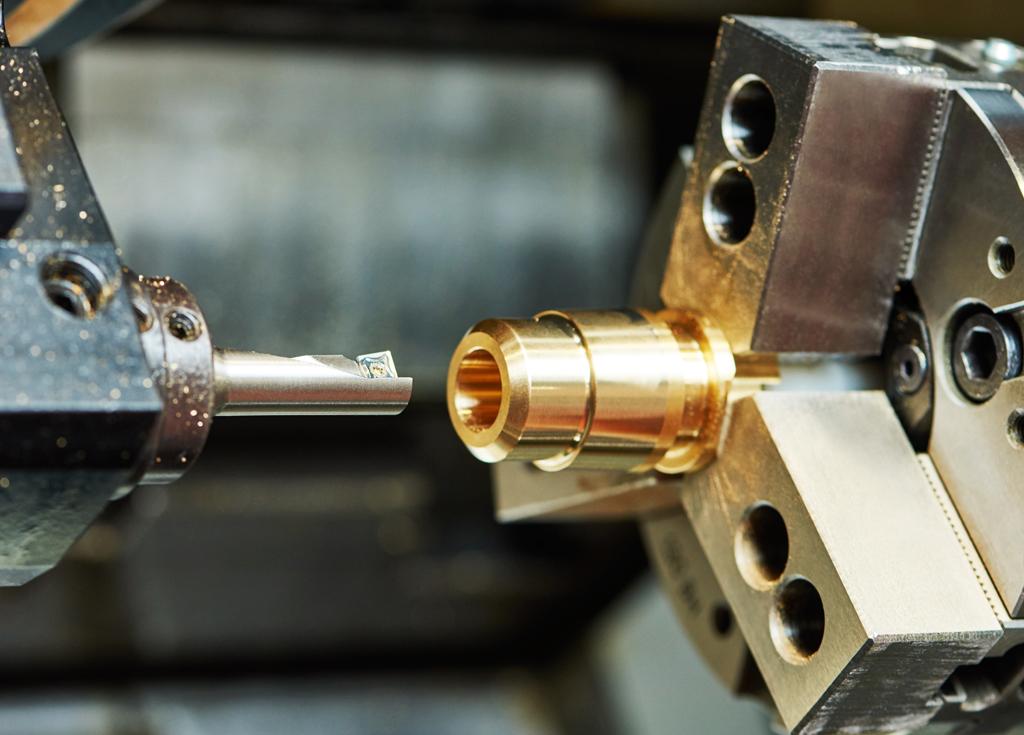

- 23 April 2025: Stock option Brass rod CW614N-CW617N - 6590 €/t See more »

- 23 April 2025: Stock option SiBRASS CW724R - 8860 €/t See more »

- 22 April 2025: Stock option Copper - 8098.20 €/t See more »

- 22 April 2025: Stock option Zinc - 2236.84 €/t See more »

- 22 April 2025: Stock option USD - 1.1476 EUR/USD See more »