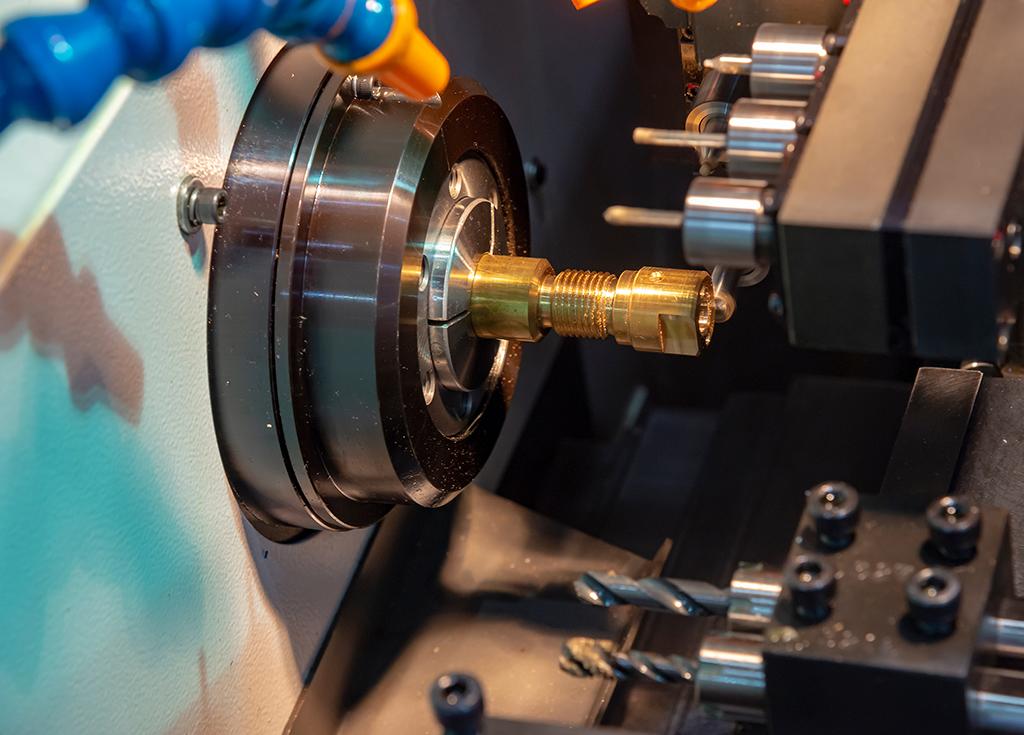

- 20 January 2026: Stock option Brass rod CW614N-CW617N - 8530 €/t See more »

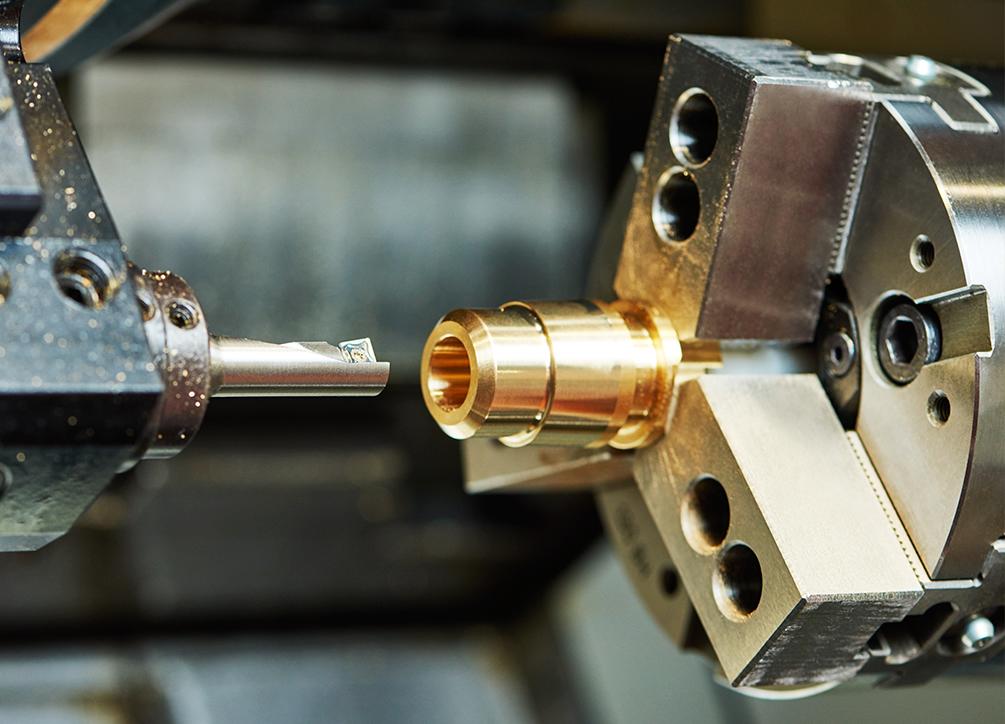

- 20 January 2026: Stock option SiBRASS CW724R - 11600 €/t See more »

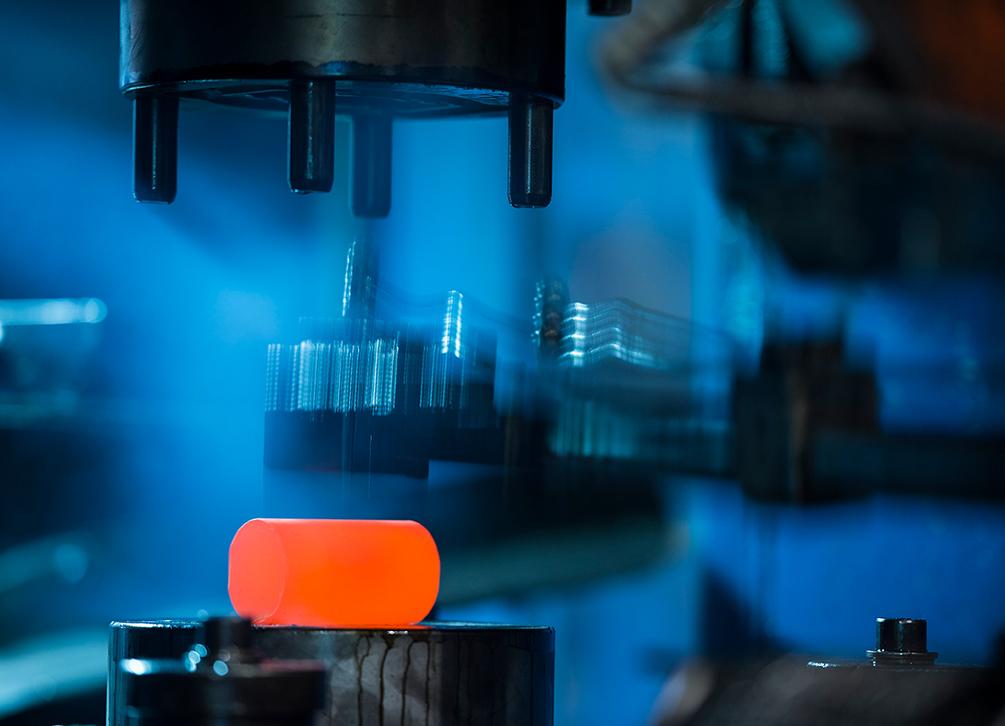

- 19 January 2026: Stock option Copper - 11177.03 €/t See more »

- 19 January 2026: Stock option Zinc - 2737.51 €/t See more »

- 19 January 2026: Stock option USD - 1.1631 EUR/USD See more »